A report from the National Fire Protection Association found that 12 percent of fires in manufacturing properties are due to electrical failure or malfunctions. This leads to $25 million in property damage that could be avoidable with early detection and prevention.

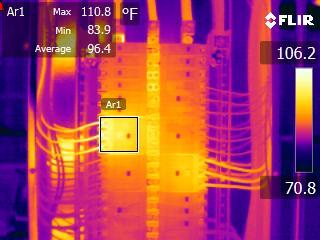

Thermal imaging allows us to inspect electrical systems with a no-contact thermal imaging camera. These images help us diagnose problems before they occur. For example, we might notice that your circuit breaker wires are overheating, which could lead to huge problems if you don’t address the problem.

Why You Should Complete Annual Utility Inspections

Companies often require these thermal images annually to provide to their insurance carrier. But even if your insurance company doesn’t require these inspections, you should do them to prevent fires or malfunctions.

Capturing these images can aid in proving you’ve completed required preventative inspections and maintenance. Or you might discover weaknesses or problem areas you need to address.

How Thermal Imaging Works

Thermal images use a device that detects abnormal temperatures within electrical components. Some common examples of areas we check for these high temperatures include:

- Fuses

- Circuit breakers

- Switchgears

Higher than normal temperatures generally occur shortly before faults. If you let these problems go until they falter, you’ll likely experience downtime. Or even worse, you might have an electrical fire on your hands.

One of the great advantages of thermal imaging is that you can log the images for reference later or to use as a comparison point to measure degradation.

Scheduled routine checks can aid you in budgeting for when you’ll need to upgrade your systems. But you can also reduce the financial impacts that downtime can have on your organization.

What Do Thermal Images Detect?

Thermal imaging for utility inspections can aid in detecting several crucial issues with your electrical systems.

- Abnormal hot spots

- Faults

- Harmonics

- Loose connections

- Overloaded circuit breakers

- Open circuits

Who Performs Infrared Thermal Imaging For Utility Inspections?

Infrared thermal imaging should be a part of your company’s preventative maintenance schedules. But that doesn’t mean you need to purchase the tools yourself or hire experts.

ACS Underground Solutions provides this service not just for utility inspections, but to detect and understand a wide variety of issues, including:

- Discovering building heat loss to fix weaknesses and improve energy conservation

- Detecting structural deficiencies through CMU wall inspections

- Diagnosing electrical system overloads

- Locating friction and wear on mechanical parts

- Finding leaks within radiant heat systems and floors

- Pinpointing high-temperature hot water leaks

- Finding steam leaks

- Preventing unnecessary digging by tracking down underground or under slab pipe leaks

To schedule thermal imaging services, call us at 203-544-7190. We’re available 24/7. For less urgent requests, you can also contact us online or via email at info@acsunderground.com.

ACS UNDERGROUND SOLUTIONS | Infrared Thermal Imaging For Utility Inspections

ACS Underground Solutions has been in business since 1997 and we continue to serve our clients during COVID 19 with the CDC safety guidance put in place. Give ACS Underground Solutions a call at 203-544-7190 to find out more about our services. Our office staff is available Monday-Friday, 8am to 5pm to answer your questions and schedule an appointment. We are a private family owned consulting company with decades of experience and deep expertise in Water Line Leak Detection, Underground Utility Locating with GPR, Underground Storage Tank Locating, Concrete Imaging & Scanning, Drain Pipe Inspections and Infrared Thermal Imaging Services. ACS Underground Solutions serves Connecticut, New York, New Jersey, Massachusetts, and Rhode Island.

Who is ACS Underground Solutions?

Who is ACS Underground Solutions? Can You Explain Thermal Imaging?

Can You Explain Thermal Imaging?